Custom Printed Greaseproof Paper Sheets: The Way to Build a Brand

Using custom printed greaseproof paper sheets is a fundamental and powerful way to build a strong brand identity in the modern food industry. In an age where the customer experience is paramount, packaging has evolved from a simple necessity into a primary communication channel. A plain, unbranded wrapper serves a function, but a custom printed sheet tells a story. It is a tangible representation of your brand's quality, personality, and attention to detail. This strategic tool can transform your products, elevate your customer's experience, and turn every sale into a marketing opportunity. This definitive guide will walk you through the entire process, from initial brand strategy to final production, revealing how to use custom printed paper to build a brand that lasts.

The Strategic Imperative of Custom Packaging

The decision to invest in custom packaging is one of the most important strategic moves a food business can make. It is a shift in mindset from viewing packaging as a simple cost to seeing it as a valuable asset. The return on this investment is measured in brand equity, customer loyalty, and a stronger, more professional market presence.

Moving Beyond a Commodity to a Brand Experience

A generic wrapper turns your carefully crafted food into a commodity. It looks the same as your competitor's product. Custom packaging instantly breaks this mold. It creates a unique and proprietary brand experience that cannot be replicated. It signals to the customer that they are not just buying a sandwich; they are buying a product from a specific, thoughtful brand. This experience is what builds a loyal following.

The Psychology of a Branded "Unboxing"

The moment a customer receives their food is a critical touchpoint. For takeaway and delivery, this "unboxing" is their first physical interaction with your brand. A beautiful, custom printed wrapper creates a moment of delight and elevates the entire experience. It makes the meal feel more special, more curated, and of a higher quality. This positive psychological effect can significantly enhance their enjoyment and perception of the food itself. For a general overview of food-safe papers, the Parchment paper page offers some useful context, though the materials are different.

How Custom Packaging Builds Customer Trust

Consistency builds trust. When a customer sees a consistent and professional brand identity across your storefront, your menu, and your packaging, it builds confidence. It shows that you are a serious and reliable business. Custom packaging is a key part of this consistent brand image. It is a tangible piece of evidence that you are committed to quality in every single detail, which builds a deep sense of trust with your customer base.

Here are the key strategic reasons to invest in custom packaging:

- Brand Differentiation: It immediately sets your product apart from competitors who use generic, unbranded packaging.

- Enhanced Customer Experience: It creates a premium, memorable, and shareable "unboxing" moment.

- Increased Brand Recognition: It puts your brand name and logo directly into your customers' hands, reinforcing recall.

- Professionalism and Authority: It projects an image of a successful, detail-oriented, and high-quality operation.

- Cost-Effective Marketing: It turns every product sold into a mobile advertisement that generates organic impressions.

Step 1: The Design and Branding Strategy

The journey to effective custom packaging begins with a strong creative strategy. Your printed paper should be a direct reflection of your brand's unique identity. This is not just about making a pretty pattern; it is about telling a story and communicating a specific message to your target audience.

Defining Your Brand Identity and Message

Before you start designing, you must have a clear understanding of your brand. What is your brand's personality? Are you fun and playful, or are you sophisticated and elegant? Are you rustic and traditional, or are you modern and minimalist? Who is your target customer, and what do you want them to feel when they interact with your brand? The answers to these questions will form the foundation of your design brief.

The Power of a Simple Greaseproof Paper Sheets Logo

For many businesses, the first and most effective step into custom printing is to use their logo. A simple, repeating pattern of your greaseproof paper sheets with a logo is a classic and powerful branding tool. It is clean, professional, and instantly connects the packaging to your brand. It is the most direct way to build brand recognition.

Evolving to a Full Custom Pattern or Illustration

Beyond a simple logo, you can create a fully custom pattern or a set of illustrations. This is the next level of brand storytelling. A custom pattern could be made from a secondary brand icon, a unique geometric shape, or a hand-drawn element. This proprietary pattern can become a recognizable brand asset in its own right. Custom illustrations can be used to tell a story about your ingredients, your history, or your brand's values.

Choosing a Color Palette that Reflects Your Brand

Color is a critical part of your design. The colors you choose should be taken directly from your established corporate branding palette. This ensures consistency across all your marketing materials. When choosing colors, consider the psychological impact. Warm colors can stimulate appetite, while earthy tones can signal a natural or organic focus. The color palette is a key part of setting the mood.

Step 2: Preparing Your Artwork for Printing

Once you have your design concept, it must be translated into a technically correct, print-ready digital file. This is a crucial step that ensures your final printed product looks sharp, clean, and professional. Errors in this stage can lead to a disappointing and costly result.

The Absolute Necessity of Vector Artwork (AI, EPS, PDF)

This is the most important technical requirement. Your design, including your logo and any other elements, must be in a vector format. The standard vector file types are Adobe Illustrator (.ai), Encapsulated PostScript (.eps), or a high-resolution PDF created from a vector program. A vector graphic is made from mathematical equations, which means it can be scaled to any size without losing any quality. A pixel-based graphic, like a .jpg or .png, will become blurry and pixelated when enlarged for printing.

Understanding Color Modes (CMYK vs. Pantone)

There are two main color systems used in professional printing. CMYK (Cyan, Magenta, Yellow, Black) is a system that mixes four colors to create a full spectrum. It is used for full-color photographic printing. The Pantone Matching System (PMS) uses pre-mixed, standardized spot colors. For most simple logo and pattern printing on greaseproof paper, Pantone colors are used. This ensures that your brand color is perfectly accurate and consistent every single time it is printed.

Laying Out a "Step-and-Repeat" Pattern

The most common design layout is a "step-and-repeat" pattern. This is where your design element is repeated in a grid or an offset pattern across the sheet. Your graphic designer will need to create a seamless tile that can be repeated without any visible breaks or lines. They will also need to consider the scale of the pattern to ensure it looks good when wrapped around your products.

Working with a Graphic Designer for Professional Results

Unless you are a professional graphic designer with experience in print production, it is highly recommended to hire one for this stage. A professional designer will be able to create a beautiful and effective design that is also technically perfect for the printing process. They will ensure your logo is in the correct vector format, your colors are set up correctly, and your final file is ready for the press. This small investment will save you a huge amount of potential frustration.

Step 3: Choosing Your Materials and Specifications

With a print-ready design in hand, the next step is to choose the physical specifications for your custom printed greaseproof paper sheets. These choices will affect the final look, feel, and functionality of your packaging.

The Base Paper: Bleached White vs. Unbleached Kraft

You will typically have a choice of two base papers. A bleached white paper is a clean, bright, and modern canvas. It allows for the most accurate and vibrant color printing. An unbleached kraft paper is a natural brown color that provides a rustic, artisanal, and eco-friendly look. The choice of base paper is a key part of your overall brand aesthetic.

The Inks: The Importance of Food-Safe and Soy-Based Options

This is a critical safety requirement that cannot be overlooked. All inks used for food packaging must be certified as food-safe and non-toxic. Reputable printers will use water-based or soy-based inks as a standard. These inks are made from food-grade ingredients and are guaranteed not to leach any harmful substances into your food. Always confirm this with your supplier.

Paper Size and Format: Sheets vs. Rolls

You will need to decide on the format of your paper. Pre-cut sheets are the most common and convenient option for most businesses. They can be ordered in a variety of standard sizes or even a custom size to fit your specific needs. For businesses that need to wrap items of many different sizes, the paper can also be supplied in a large roll.

Paper Weight and Thickness (GSM)

The thickness of the paper, measured in Grams per Square Meter (GSM), is another important choice. A standard GSM is suitable for most general uses like wrapping a sandwich or lining a tray. For heavier or oilier items, or for a more premium, durable feel, you might choose a heavier-weight paper with a higher GSM. Your supplier can provide samples of different weights.

Step 4: The Printing and Production Process

The final stage is the production of your custom paper. This is a professional printing process that involves several steps, and it is important to understand the timeline and the key checkpoints.

An Overview of the Flexographic Printing Method

As we have discussed, the most common printing method is flexography. This high-speed process is perfect for large runs. The setup for this process involves creating custom printing plates for your design. This initial setup has a cost, which is why there are minimum order quantities.

The Critical Proofing and Approval Stage

Before the full order is printed, you must approve a proof. A digital proof (a PDF) is standard. However, for a new design, it is always highly recommended to request a physical proof. This is an actual printed sample of your paper. It allows you to check the colors, the print quality, and the overall look and feel before you commit to printing thousands of sheets. Do not skip this step.

Understanding Minimum Order Quantities (MOQs)

Because of the setup costs of the printing press, custom printing is only economical in large quantities. Every printer will have a minimum order quantity (MOQ). This is the smallest number of sheets you can order. This can be several thousand sheets. A new business must be prepared for this initial investment and must have the space to store the product.

Typical Production and Shipping Lead Times

Custom printing is not an overnight process. The entire cycle, from approving the artwork to receiving the final product, can take several weeks. You must factor this lead time into your planning. Always order your next batch of paper well before you are about to run out of your current stock.

How to Use Your Custom Printed Sheets for Maximum Impact

Once your beautiful custom paper arrives, the fun begins. There are many ways to use it to create a professional and memorable experience for your customers.

For Wrapping Sandwiches, Burgers, and Takeaway Foods

This is the primary application. A custom wrap instantly transforms a simple takeaway item into a branded product. It looks great, protects the food, and keeps the customer's hands clean.

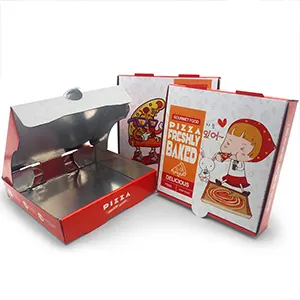

For Lining Trays, Baskets, and Boxes

Lining your serving vessels with your custom paper creates a fully branded and cohesive presentation. It is a simple touch that shows a high level of professionalism.

For Enhancing the Presentation of Baked Goods

A bakery can use custom paper to wrap individual items, line pastry boxes, or even as a decorative band around a cake. It adds a layer of artisanal quality to the presentation. This is the ultimate goal of all printed greaseproof paper sheets.

Sourcing and Partnership: Finding the Right Printer

Choosing the right supplier is key to a successful project. You need a partner who is an expert in food-safe packaging.

Key Qualities of a Good Food Packaging Supplier

A good supplier will be transparent about their materials and safety certifications. They will have a strong portfolio of work. They will have a helpful and knowledgeable customer service team. Look for a company that specializes in food packaging, not a general commercial printer.

Requesting Samples and Evaluating Quality

Before you commit, ask for a sample pack. This will allow you to see the quality of their different paper stocks and the sharpness of their printing. The quality of their samples is the best indicator of the quality of the work they will do for you. When you decide to order, you are buying a full order of custom greaseproof paper sheets. It's best to be sure of the quality. This is true for all printed greaseproof paper sheets available on the market.

Final Thoughts

Investing in custom printed greaseproof paper sheets is one of the smartest and most effective branding decisions a food business can make. It is a cost-effective way to build a professional brand image, enhance the customer experience, and create a powerful marketing tool that works for you with every single sale. By developing a thoughtful design, preparing the artwork correctly, and working with a reputable supplier, any business can leverage this amazing product. It is the simple, tangible detail that shows your customers you care, and it is a proven way to build a brand that people will remember and return to time and time again.

JERL has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of JERL Packaging!