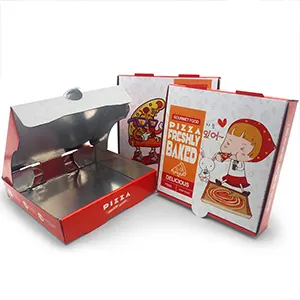

Brugerdefinerede fedtsugende plader: Nem måde at skille sig ud i emballage

Brugerdefinerede fedtsugende papirark tilbyder en direkte vej for fødevarevirksomheder til at skille sig ud på et overfyldt marked. Norm, Hyldeemballage er funktionel, men forglemmelig. Tilpasning forvandler denne grundlæggende nødvendighed til et kraftfuldt brandingværktøj. Det involverer at skræddersy alle aspekter af papiret, fra dens størrelse og vægt til dens trykte design, for at skabe en unik brandsignatur. Denne vejledning giver et detaljeret indblik i processen og fordelene ved at bruge brugerdefinerede ark. Forståelse af disse elementer giver en virksomhed mulighed for at skabe en mindeværdig emballageoplevelse, der fanger kundernes opmærksomhed.

Hvorfor tilpasning er vigtig i fødevareemballage

I den moderne fødevareindustri, Kundeoplevelsen rækker langt ud over smagen af maden. Emballage er et kritisk kontaktpunkt, der former opfattelsen og opbygger brandidentitet. At vælge tilpassede løsninger frem for standardløsninger er et strategisk valg, der giver betydelige fordele i branddifferentiering og kundeengagement.

Bevæger sig ud over generisk: Grænserne for standardemballage

Generisk emballage tjener sit grundlæggende formål om at indeholde fødevarer, Men det gør intet for at opbygge et brand. En almindelig hvid eller brun indpakning er et tomt lærred, En forspildt mulighed for at kommunikere. Det får en virksomhed til at ligne enhver anden, undlader at skabe et mindeværdigt indtryk. Standardemballage kan ikke formidle et brands personlighed, værdier, eller forpligtelse til kvalitet. Det er en rent funktionel vare, der ikke tilføjer nogen værdi til kundeoplevelsen og ikke tilskynder til brandgenkaldelse eller loyalitet.

Oprettelse af en unik brandsignatur

Tilpasning giver en virksomhed mulighed for at skabe en unik visuel identitet, der er øjeblikkeligt genkendelig. Denne mærkesignatur er bygget af en kombination af logoer, Farver, mønstre, og endda papirets specifikke fornemmelse. Når kunderne ser denne unikke emballage, De forbinder det straks med mærket. Denne øjeblikkelige anerkendelse er uvurderlig på et travlt marked. Det hjælper en virksomhed med at skære igennem støjen og etablere en tydelig tilstedeværelse. En stærk brandsignatur får et produkt til at føles mere professionelt og gennemtænkt forberedt.

Forbedring af kundens unboxing-oplevelse

Handlingen med at modtage og pakke mad ud er en vigtig del af den samlede oplevelse. Brugerdefinerede fedtsugende plader kan gøre dette øjeblik til noget særligt. Et ark, der er skåret til den perfekte størrelse til et bestemt produkt, føles bevidst og premium. Et smukt trykt design tilføjer et element af glæde og opdagelse. Denne forbedrede "Unboxing" Erfaring får måltidet til at føles mere værdifuldt. Det viser kunderne, at virksomheden går op i præsentation, hvilket igen tyder på et højt niveau af pleje af selve maden.

Psykologien i "Lavet til dig"

Tilpasning skaber en opfattelse af eksklusivitet og personlig opmærksomhed. Når emballagen er tydeligt designet til et bestemt brand eller produkt, Det føles mindre som en masseproduceret vare og mere som noget specielt tilberedt. Denne "Lavet til dig" Følelse vækker dyb genklang hos kunderne. Det får dem til at føle sig værdsat og forstået af brandet. Denne psykologiske forbindelse er en stærk drivkraft for kundetilfredshed og loyalitet. Det fremmer et forhold, der går ud over en simpel transaktion.

Elementerne i tilpasning: Et dybere kig

Ægte tilpasning af fedtsugende papir involverer meget mere end blot at trykke et logo. Det er en mangefacetteret proces, hvor hvert element i papiret kan skræddersys til at imødekomme et brands specifikke behov. At forstå disse forskellige elementer er det første skridt i at skabe virkelig effektiv og unik emballage.

Tilpasning af arkstørrelse og form

En af de mest praktiske og virkningsfulde former for tilpasning er at justere størrelsen og formen på arkene. Standardplader resulterer ofte i spild, da de skal trimmes ned, eller de giver en akavet pasform. Specialskårne ark produceres til de nøjagtige dimensioner, der er nødvendige for at pakke en bestemt vare ind, som en burrito eller en sandwich, eller til at beklæde en bestemt bakke eller kurv. Denne perfekte pasform ser ikke kun mere professionel ud, men forbedrer også effektiviteten i et travlt køkken. Det eliminerer den tid, personalet bruger på at skære papir og reducerer materialespild, hvilket kan føre til omkostningsbesparelser over tid.

Valg af papirtype og -vægt (GSM)

Selve papiret kan tilpasses. Virksomheder kan vælge mellem bleget hvidt papir for en rengøring, moderne udseende, eller ubleget brunt papir for en mere rustik, naturlig æstetik. Papirets vægt, målt i gram pr. kvadratmeter (GSM), er en anden nøglevariabel. Et papir med lavere GSM er lettere og mere fleksibelt, velegnet til sarte genstande. Et papir med højere GSM er tykkere, mere holdbar, og har en mere premium følelse. Valget af papirtype og vægt skal stemme overens med brandets image og de fysiske krav til den mad, der serveres.

Rollen af brugerdefineret udskrivning og design

Det mest synlige element i tilpasningen er det trykte design. Det er her, et brands visuelle identitet kommer til live. Ud over blot et logo, brugerdefinerede trykte fedtsugende papirark kan indeholde indviklede mønstre, specifikke mærkefarver, Taglines, eller illustrationer. Designmulighederne er næsten ubegrænsede. Et veludført design forvandler papiret til et storytelling-værktøj, Kommunikere brandets personlighed og værdier direkte til kunden på det mest kritiske tidspunkt i deres oplevelse.

Differentiering af brugerdefineret fedtsugende papir fra alternativer

For at forstå, hvad der gør brugerdefineret fedtsugende papir unikt, skal du sammenligne det med andre muligheder. For eksempel, Pergamentpapir behandles med silikone, hvilket gør den ideel til bagning ved høj varme på grund af dens non-stick egenskaber. Dog, Dens primære funktion er teknisk, ikke æstetisk. Vokspapir er uegnet til varm mad og tilbyder begrænset brandingpotentiale. Specialfremstillet fedtsugende papir er specielt designet til præsentation og indpakning af en lang række fødevarer, Tilbyder den bedste kombination af ydeevne, sikkerhed, og brandbarhed.

Design- og illustrationsprocessen for brugerdefinerede ark

At skabe det perfekte design til brugerdefinerede fedtsugende plader er en detaljeret proces. Det kræver en blanding af kreativ vision og teknisk præcision. Et vellykket resultat afhænger af en klar forståelse af designprincipper og de specifikke krav til trykprocessen.

Fra koncept til en printklar fil

Processen starter med et designkoncept. Denne oprindelige idé bør være i overensstemmelse med brandets overordnede identitet. Konceptet udvikles derefter til et digitalt design, ofte ved hjælp af professionel grafisk designsoftware. Det sidste trin er at konvertere dette design til en "Klar til print" fil. Dette er et teknisk format, som producenten kan bruge til at fremstille trykpladerne. Denne fil skal være præcis for at sikre, at det endelige produkt er af høj kvalitet.

Centrale designprincipper for fødevareemballage

Der er flere nøgleprincipper, der skal være retningsgivende for designet. Enkelhed er ofte meget effektiv; Et rent design er lettere at genkende og ser professionelt ud. Designet skal være skalerbart, hvilket betyder, at det ser godt ud både tæt på og på afstand. Farvevalg er afgørende og bør være i overensstemmelse med mærkets etablerede palet. Vigtigst, Designet skal være i overensstemmelse med brandets stemme og personlighed, om det er legende, elegant, eller rustik.

Tekniske illustrationskrav til printere

Printere har specifikke tekniske krav til illustrationsfiler. De fleste kræver vektorfiler (formater som . AI, .EPS, eller .PDF) fordi de kan skaleres uden at miste kvalitet. De vil også angive farvetilstande, såsom Pantone Matching System (PMS) til præcise staffagefarver eller CMYK til fuldfarveudskrivning. Designet skal muligvis også omfatte "bløde," hvilket er ekstra plads rundt om kanterne for at sikre, at trykket går hele vejen til skærelinjen. At forstå og følge disse tekniske regler er afgørende for at opnå et professionelt resultat.

Vigtigheden af den digitale korrekturfase

Før en fuld produktion, Printeren leverer en digital korrektur. Dette er en digital mock-up, der viser præcis, hvordan designet vil blive trykt på arket. Dette er den sidste mulighed for at tjekke for eventuelle fejl, såsom stavefejl, forkerte farver, eller placeringsproblemer. Det er afgørende at gennemgå dette bevis med ekstrem omhu. Godkendelse af et forkert bevis kan føre til en dyr fejl. Korrekturfasen er et vigtigt kvalitetskontroltrin, der sikrer, at det endelige produkt lever op til alle forventninger.

Bestilling og indkøb af dit brugerdefinerede fedtsugende papir

Når et design er færdigt, Den næste fase er at finde en produktionspartner og navigere i bestillingsprocessen. Dette indebærer omhyggelig research, Klar kommunikation, og en forståelse af produktionstidslinjen. At vælge den rigtige leverandør er lige så vigtigt som at skabe det rigtige design.

Sådan finder du den rigtige produktionspartner

En pålidelig produktionspartner vil have en dokumenteret track record. Se efter leverandører med en stærk portefølje, positive kundeudtalelser, og klar dokumentation for fødevaresikkerhedscertificeringer. De skal være i stand til at levere prøver af deres papir og trykarbejde, så du kan vurdere kvaliteten på første hånd. En god partner vil også tilbyde vejledning og støtte gennem hele design- og bestillingsprocessen. De skal fungere som ekspertrådgiver, ikke bare en printer.

Navigering i tilbuds- og bestillingsprocessen

Når du har et design, Du kan anmode om tilbud fra potentielle leverandører. Citatet skal være fyldestgørende, Detaljering af prisen pr. ark, eventuelle oprettelsesgebyrer for trykplader, og forsendelsesomkostninger. Når du er klar til at bestille din Fedtsugende papirark brugerdefineret Lavet, Du skal typisk levere den endelige illustrationsfil og godkende den digitale korrektur. Leverandøren vil derefter give en estimeret tidslinje for produktion og levering.

Forståelse af leveringstider og forsendelse

Brugerdefinerede produkter laves på bestilling, så de er ikke tilgængelige for øjeblikkelig forsendelse. Den tid, det tager fra godkendelse af korrekturen til modtagelse af det endelige produkt, kaldes leveringstiden. Dette kan variere fra et par uger til et par måneder, afhængig af leverandøren og ordrens kompleksitet. Virksomheder skal indregne denne leveringstid i deres planlægning for at sikre, at de ikke løber tør for emballage.

Nøglespørgsmål at stille en potentiel leverandør

Før du forpligter dig til en leverandør, Det er klogt at stille flere vigtige spørgsmål. Dette er med til at sikre, at de passer til din virksomheds behov.

- Hvad er dine fødevaresikkerhedscertificeringer?

- Hvad er din mindste ordremængde (MOQ)?

- Kan du give en fysisk prøve af et lignende tidligere projekt?

- Hvad er dine specifikke krav til illustrationsfiler?

- Hvad er den estimerede leveringstid fra korrektur til levering?

Personalisering: Det næste niveau af tilpasning

Mens tilpasning skræddersyr emballagen til et brand, Personalisering har til formål at skræddersy det til kunden. Det er en mere avanceret strategi, der kan skabe en endnu dybere forbindelse og fremme stærk loyalitet. Det får kunden til at føle sig individuelt anerkendt og værdsat.

Hvordan tilpasning adskiller sig fra standardtilpasning

Tilpasning handler om at afspejle brandets identitet på emballagen. Personalisering handler om at skabe en oplevelse, der føles unik for kunden eller en bestemt lejlighed. Det forvandler emballagen fra et mærkevareobjekt til et stykke kommunikation. Denne tilgang kræver mere kreativitet, men kan give stærke resultater i kundeengagement.

Brug af personlige fedtsugende papirark til kampagner

En effektiv strategi er at bruge Personlige fedtsugende papirark til specifikke begivenheder eller kampagner. En virksomhed kan skabe et unikt design til en ferie, En lokal festival, eller et firmajubilæum. Dette får emballagen til at føles rettidig og speciel. Kunderne sætter pris på disse nye detaljer, og det giver dem en grund til at engagere sig i brandet i disse specifikke perioder. Det viser, at brandet er dynamisk og lydhør.

Skab en interaktiv oplevelse med emballage

Personalisering kan også være interaktiv. Et brugerdefineret ark kan designes som et puslespil eller et spil til børn. En QR-kode kan inkluderes, der linker til en "hemmelig" menupunkt eller en tilmeldingsformular til en konkurrence. Disse interaktive elementer engagerer kunden ud over selve måltidet. De skaber en sjov, mindeværdig oplevelse, som folk sandsynligvis vil tale om og dele med andre.

Værdien i at få kunderne til at føle sig unikke

I sin kerne, Personalisering handler om at få hver enkelt kunde til at føle sig vigtig. Selv små bevægelser, som et design, der giver personalet mulighed for at skrive kundens navn på indpakningen, kan have en betydelig indvirkning. Denne anerkendelse af individet opbygger et stærkt følelsesmæssigt bånd. Kunder, der føler en personlig forbindelse til et brand, er langt mere tilbøjelige til at blive loyale, langsigtede fortalere.

Sourcing og logistik til din virksomhed

De praktiske aspekter af indkøb og håndtering af specialemballage er vigtige for problemfri drift. En virksomhed skal overveje, hvor den skal købe sine materialer, Sådan administrerer du lagerbeholdning, og de langsigtede fordele ved et godt leverandørforhold.

Overvejelser i forbindelse med internationale og lokale indkøb

Virksomheder kan vælge at arbejde med lokale eller internationale leverandører. Lokale leverandører kan tilbyde hurtigere kommunikation og kortere leveringstider. Internationale leverandører kan tilbyde mere konkurrencedygtige priser eller specialiserede muligheder. Beslutningen afhænger af en virksomheds prioriteringer med hensyn til omkostninger, fart, og kommunikation. Det er vigtigt at afveje fordele og ulemper ved hver tilgang omhyggeligt.

Søgning efter leverandører til specifikke markeder

Processen med at finde en leverandør involverer ofte at undersøge muligheder fra leverandører i specifikke regioner. At undersøge producenter, der henvender sig til dit marked, kan hjælpe med at sikre, at de forstår lokale regler og forsendelseslogistik. Denne fokuserede søgning kan føre til at finde en partner, der passer bedre til dine specifikke operationelle behov.

Lagerstyring for brugerdefinerede produkter

Fordi brugerdefinerede fedtsugende plader kommer med leveringstider og ofte MOQ'er, Lagerstyring er nøglen. En virksomhed skal planlægge ordrer i god tid for at undgå at løbe tør. Det kræver også tilstrækkelig lagerplads til at rumme bulkordren. At balancere omkostningsfordelene ved en stor ordre med realiteterne i lager og likviditet er en kritisk operationel opgave.

Den langsigtede værdi af et pålideligt leverandørforhold

Udvikling af en stærk, langvarige relationer med en leverandør er meget værdifulde. En leverandør, der forstår dit brand, kan tilbyde bedre service, foreslå nye ideer, og potentielt tilbyde bedre priser over tid. Dette partnerskab giver stabilitet og ro i sindet, at vide, at en kritisk komponent i din branding og drift er i pålidelige hænder.

Resumé

Brugerdefinerede fedtsugende papirark er et kraftfuldt og tilgængeligt værktøj til enhver fødevarevirksomhed, der sigter mod at skille sig ud. Ved at bevæge sig ud over generisk emballage, Et brand kan skabe en unik signatur, der forbedrer kundeoplevelsen og opbygger en mindeværdig identitet. Processen involverer gennemtænkt tilpasning af størrelse, materiale, og design, alt sammen styret af en klar brandstrategi. Sourcing fra en pålidelig partner sikrer en høj kvalitet, fødevaresikkert produkt, der ser professionelt ud. Endelig, brugerdefinerede fedtsugende plader er ikke bare en indpakning; de er en nøgleingrediens i opbygningen af et særskilt og succesfuldt brand.

JERL har arbejdet hårdt på vejen med specialemballage. Næste gang, når du føler behov for at imponere nogen med dit brand, tænk på JERL Packaging!