Printed Greaseproof Sheets: Branding Benefits for Restaurants

Printed greaseproof paper sheets are a critical marketing tool for modern restaurants and food businesses. They turn standard food packaging into a dynamic branding opportunity. This simple addition elevates the customer experience from ordinary to memorable. This guide explores the strategic benefits, material science, and design principles behind using printed greaseproof paper. Understanding these elements helps businesses create packaging that is both functional and visually appealing. Custom branding on these sheets reinforces a restaurant's identity with every single order.

The Strategic Value of Printed Greaseproof Sheets

Using printed greaseproof sheets is a strategic business decision. It moves beyond basic necessity into the world of brand marketing. This packaging choice directly influences customer perception and engagement. A well-designed sheet communicates professionalism and attention to detail. It can transform a simple meal into a branded experience that resonates with customers long after they have finished eating.

Elevating Brand Identity with Every Order

Brand identity is the collection of all elements that a company creates to portray the right image to its consumer. Printed greaseproof paper sheets are a direct and tangible expression of this identity. Every time a customer unwraps a sandwich or pulls fries from a basket, they interact with the brand's logo and design. This consistent exposure helps build brand recall. It reinforces the visual elements of the business, making it more recognizable. A unique pattern or a clever design can make a brand stand out in a competitive marketplace. It turns a disposable item into a piece of the brand's story.

Creating a Memorable Customer Experience

The customer experience encompasses every interaction a person has with a business. Packaging is a significant part of this journey, especially for takeout and delivery. A plain wrapper is forgettable. A custom printed sheet, however, creates a moment of delight. It shows that the business cares about presentation. This small detail can make the customer feel valued. It contributes to an overall positive impression of the meal and the establishment. A memorable unboxing or unwrapping experience is something people remember and often share with others.

Perceived Quality and Professionalism

The quality of packaging often influences the perceived quality of the product inside. When food is presented on or wrapped in custom branded greaseproof paper sheets, it appears more professional. This signals to the customer that the restaurant invests in quality at every level. It builds trust and suggests that the food itself is of a higher standard. This perception is important for commanding premium prices and building a reputation for excellence. It is a subtle cue that speaks volumes about the business's commitment to quality.

Social Media Marketing Opportunities

In an age of visual social media, presentation is everything. Printed greaseproof paper sheets create an "Instagrammable" moment. Customers are more likely to take and share photos of their food when it is presented attractively. A wrapper featuring a business's logo, social media handle, or a unique hashtag becomes a form of user-generated content. This organic marketing is incredibly valuable. It exposes the brand to a wider audience at no additional cost. The packaging essentially becomes a backdrop for free advertising created by satisfied customers.

Understanding the Material: What Makes Printed Greaseproof Paper Effective?

The effectiveness of printed greaseproof paper stems from its specialized material properties and the safety of the printing process. It is not just about aesthetics; the paper must perform its primary function of resisting grease while ensuring the printed design is safe for food contact. A deep understanding of these technical aspects is crucial for any food business.

The Science Behind Grease Resistance

Greaseproof paper achieves its signature quality through a mechanical process, not a chemical one. The paper pulp is heavily processed to create very fine cellulose fibers. These fibers are then compressed under immense pressure in a machine called a supercalender. This process flattens the fibers and drastically reduces the microscopic pores within the paper. The resulting dense, non-porous structure physically blocks oil and grease molecules from passing through. This method ensures the paper's grease resistance is an inherent part of its structure.

Ensuring Food-Safe Inks and Printing Processes

When printing on any food-contact surface, safety is the top priority. Reputable manufacturers of printed greaseproof paper sheets use food-safe inks. These are typically soy-based or water-based inks that are free from harmful chemicals and heavy metals. They are formulated to be stable and non-toxic, ensuring that no ink components migrate into the food. The printing process itself must also adhere to strict hygiene standards. A trustworthy supplier will be able to provide documentation and certifications confirming that both their paper and their inks comply with food safety regulations.

Comparing Printed Greaseproof Paper to Other Options

It is important to distinguish printed greaseproof paper from other common food papers. For example, Parchment paper is coated with silicone, which gives it superior non-stick properties and high heat resistance. While it can be printed on, its primary use is for high-temperature baking. Wax paper, which is coated with paraffin wax, is not suitable for printing with food-safe inks for hot food applications. The wax can melt, compromising the design and potentially the food. Printed greaseproof paper offers the ideal balance of grease resistance, printability, and moderate heat tolerance for wrapping and presentation.

Durability and Performance Under Commercial Conditions

A professional kitchen environment is demanding. Packaging materials must be strong enough to withstand handling, heat, and moisture. Printed greaseproof paper sheets are designed for this. Their dense fiber structure gives them good tensile strength, so they resist tearing when wrapping items. They hold up well against the heat of freshly cooked foods like burgers or fried chicken. While not fully waterproof, they can handle the steam and condensation from hot foods without quickly falling apart. This durability ensures the packaging maintains its integrity and its branded appearance from the kitchen to the customer.

Designing Effective Branded Greaseproof Paper Sheets

The design printed on greaseproof sheets is a direct reflection of the brand. An effective design is more than just a logo; it is a thoughtful composition of visual elements that tells a story. Creating a successful design requires attention to branding principles, color theory, and technical artwork specifications.

Key Principles of Effective Packaging Design

A strong design on greaseproof paper follows a few key principles. Simplicity is often best. A clean, uncluttered design with a clear logo is more easily recognizable than a busy, complex one. Repetitive patterns using a brand's logo or a unique icon can be very effective. This ensures the brand is visible no matter how the paper is folded or cut. The scale of the design elements is also important. They must be large enough to be clear but not so large that they overwhelm the food. The goal is to complement the product, not distract from it.

Choosing a Design That Reflects Your Brand's Story

The design should align with the restaurant's overall brand personality. A rustic farm-to-table eatery might choose an unbleached brown paper with a simple, earthy-toned logo. A fun, vibrant ice cream shop could use a bright, playful pattern on bleached white paper. The typography, colors, and imagery should all be consistent with the brand's existing marketing materials, from the menu to the website. This creates a cohesive and professional brand image that customers can easily connect with.

Technical Specifications for Artwork Submission

When working with a printing supplier, providing artwork in the correct format is essential for a high-quality result. Most printers require vector files, such as those created in Adobe Illustrator (.AI, .EPS, or .PDF). Vector graphics can be scaled to any size without losing quality, which is vital for printing. Raster images, like JPEGs or PNGs, can become blurry or pixelated. It is also important to consider color profiles. Printers often use the Pantone Matching System (PMS) for precise color accuracy or CMYK for full-color designs. Understanding these technical requirements ensures the final product looks exactly as intended.

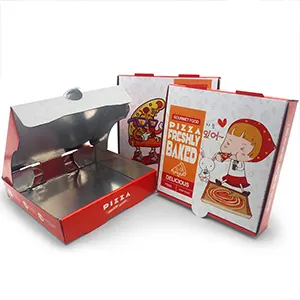

Creating a Cohesive Look with Other Packaging

The printed greaseproof sheet is just one component of a restaurant's packaging suite. For a truly professional look, it should coordinate with other items like bags, boxes, and cups. Some businesses take this a step further. They combine their printed greaseproof paper sheets with coloured parcel tape to seal their packages. This creates a fully branded and secure solution for delivery and takeout orders. A cohesive packaging strategy reinforces the brand at every touchpoint and shows a high level of attention to detail.

The Process of Ordering Custom Printed Greaseproof Paper

Ordering custom printed packaging for the first time can seem like a complex process. However, by understanding the steps involved and knowing what to look for in a supplier, a business can navigate it smoothly. From initial design to final delivery, a methodical approach ensures a successful outcome and a product that meets all expectations.

How to Select a Reliable Supplier

Choosing the right supplier is the most important step. A reliable partner will have a strong portfolio of past work and positive customer reviews. They should be transparent about their materials and printing processes, readily providing food safety certifications. Inquire about their design support capabilities; some suppliers have in-house designers who can help refine your artwork. When evaluating options, it is helpful to review suppliers in different markets to understand the range of services available. Clear communication and good customer service are also key indicators of a trustworthy supplier.

Understanding Minimum Order Quantities (MOQs) and Pricing

Custom printing typically involves minimum order quantities, or MOQs. This is the smallest quantity of sheets a supplier is willing to produce in a single run. MOQs can vary greatly, so it is important to find a supplier whose minimums align with your business's needs and storage capacity. Pricing is usually tiered, meaning the cost per sheet decreases as the order volume increases. When requesting a quote, be sure it includes all costs, such as setup fees, printing plates, and shipping. This avoids any unexpected expenses later on.

The Proofing and Approval Process

Before the full order is printed, a supplier will provide a digital proof of the artwork. This is a critical step. The proof is a digital mock-up showing how the design will look on the paper, including its size, color, and placement. It is essential to review this proof very carefully. Check for any typos, incorrect colors, or layout issues. Any changes must be requested at this stage. Once the proof is approved, the design is sent to production. A thorough review of the proof prevents costly mistakes and ensures the final product is perfect.

From Design to Delivery: A Step-by-Step Overview

The entire process generally follows a clear sequence. It begins with the initial design concept and artwork preparation. Next is selecting a supplier and requesting a quote. Once a supplier is chosen, the artwork is submitted, and a digital proof is created and reviewed. After the proof is approved, the order moves into production. This involves printing, cutting, and packaging the greaseproof sheets. The final step is shipping and delivery. Understanding this timeline helps a business plan accordingly and manage its inventory effectively.

Practical Applications and Branding Benefits in Action

The true value of printed greaseproof sheets is seen when they are put to use. Across different sectors of the food industry, this simple product serves as both a practical tool and a marketing asset. Its applications are diverse, but the branding benefits remain consistent.

For Quick-Service Restaurants: Burgers, Wraps, and Fries

Quick-service restaurants thrive on speed and consistency. Printed greaseproof paper is perfect for this environment. Wrapping a burger or a burrito in branded paper elevates the product's appearance instantly. Using a sheet as a liner in a basket of fries or onion rings adds a professional touch and helps absorb excess oil. The branding is front and center, reinforcing the restaurant's identity with every single item served.

For Bakeries and Cafes: Pastries, Cakes, and Sandwiches

Bakeries and cafes often focus on the quality and craftsmanship of their products. Their packaging should reflect this. A custom printed sheet used to wrap a sandwich or line a pastry box shows a commitment to detail. It can also be used as a "belly band" around a small cake box for a touch of elegance. This type of thoughtful packaging enhances the artisanal feel of the products and justifies a premium price point.

For Food Trucks and Market Stalls: A Competitive Edge

Food trucks and market stalls operate in crowded, visually competitive spaces. Branded packaging is an effective way to stand out. A customer walking away with food wrapped in a distinctively printed sheet becomes a walking advertisement. It catches the eye of other potential customers and helps build brand recognition in a busy setting. It is a simple, cost-effective way to gain a marketing advantage over competitors with generic packaging.

A Summary of Key Branding Advantages

The benefits of using printed greaseproof paper sheets are clear and impactful. They offer a unique way to connect with customers and strengthen a brand's market presence.

- Increased Brand Recall: Consistent exposure to your logo and design makes your brand more memorable.

- Enhanced Customer Perception: Custom packaging signals quality and professionalism, improving how customers view your products.

- Encourages Social Sharing: Attractive packaging leads to more user-generated content on social media, providing free marketing.

- Professional and Hygienic Presentation: It offers a clean, safe, and visually appealing way to serve food.

- Cost-Effective Marketing Channel: It turns a necessary packaging expense into a powerful promotional tool.

Maximizing the Impact of Your Printed Packaging

Simply printing a logo on a sheet of paper is just the first step. To get the most out of this branding tool, businesses can employ several creative strategies. These tactics can increase customer engagement, drive traffic to online platforms, and turn packaging into an interactive experience.

Integrating Social Media Call-to-Actions in Your Design

An effective design can do more than just display a logo. It can actively encourage customer engagement. Including social media handles directly on the paper prompts customers to connect with the brand online. A simple phrase like "Find us @YourBrandName" can drive significant traffic to social profiles. A unique hashtag for a specific campaign or for user photos can also be printed on the sheet. This encourages customers to use the tag when they post pictures, making it easy for the business to find and share user-generated content.

Using QR Codes for Menus, Promotions, or Feedback

QR codes offer a bridge between the physical packaging and the digital world. A small QR code can be incorporated into the design of the greaseproof sheet. This code can link to a variety of online resources. It could lead to the full online menu, allowing customers to easily plan their next order. It could also link to a special promotion or a coupon for their next visit. Another powerful use is linking to a feedback form or a review site. This makes it simple for customers to share their experience, providing the business with valuable insights.

The Difference Between Generic and Custom Printed Greaseproof Paper Sheets

While generic, unprinted greaseproof paper is functional, it offers no branding value. It is a missed marketing opportunity. The decision to invest in custom printed greaseproof paper sheets is a decision to invest in brand building. Custom printing allows a business to control its message and visual identity completely. It communicates a level of care and professionalism that generic packaging cannot match. It is a key differentiator in a crowded market.

How Branded Greaseproof Paper Sheets Reinforce Marketing Campaigns

Branded packaging can be a dynamic part of a larger marketing campaign. For a seasonal promotion or a new product launch, a business can create a special, limited-edition printed sheet. This creates excitement and makes the campaign more memorable. For example, a holiday-themed design can be used in December, or a special pattern can be used to celebrate an anniversary. This shows that the brand is current and actively engaging with its customers. It makes the packaging a relevant and timely piece of the marketing mix.

Summary

Printed greaseproof paper sheets are an essential tool for any restaurant or food business serious about branding. They transform a functional necessity into a powerful marketing asset that enhances brand identity, improves the customer experience, and encourages social sharing. By understanding the material's properties, following sound design principles, and choosing the right supplier, a business can create packaging that is both beautiful and effective. These sheets offer a simple yet impactful way to communicate quality and professionalism, making them a wise investment for any food service operation looking to strengthen its brand.

JERL has been working hard on the road of custom packaging. Next time when you feel the need to impress someone with your brand, think of JERL Packaging!